I think people who use power drills with those screwdriver “drill bits” are just plain lazy.

I had a new ceiling fan installed yesterday, and the installation guy came over with a power drill fitted with the Phillips screwdriver bit to do his job, and he used it on everything. The fan came with the blades and motor hub separately, so some assembly was required. Just have a look at the result.

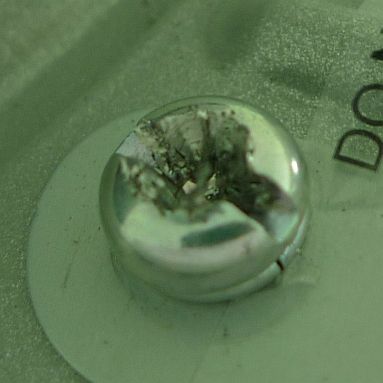

Here’s a view from the top. If not for the fact that this screw has a groove into which you can insert a flathead screwdriver, you probably won’t be able to remove this at all.

Here’s a view from the top. If not for the fact that this screw has a groove into which you can insert a flathead screwdriver, you probably won’t be able to remove this at all.

I actually needed to unscrew the bottom cover (which they term the canopy) to check if there’s a serial number printed on the motor hub. I’ve tried 3 different Phillips screwdriver and none of them can grip the screw properly.

I actually needed to unscrew the bottom cover (which they term the canopy) to check if there’s a serial number printed on the motor hub. I’ve tried 3 different Phillips screwdriver and none of them can grip the screw properly.

The thing about using a power drill is it’s powerful – it really jams the screw in there tight. But if you abuse or misuse it like this, you will probably have a hard time trying to remove the screws, and when you do, you have to find a replacement screw.

So, why couldn’t the guy just have used a regular Phillips screwdriver? I think he was just fucking lazy. How would you feel if your factory-assembled products came with stripped screws like that?

That’s why I prefer socket head cap screws or torx. Nothing of this slipping business there. But I suspect the ‘installation guy’ doesn’t know how to adjust the torque setting on his machine properly – or he just doesn’t give a damn. It’s not his ceiling fan after all.

The thing is you usually don’t get to choose what kind of screws the products ship with, and finding a suitable screw is a hassle as well. If done properly, it wouldn’t really matter what kind of screws came with the product.

As for the guy, I think his aim was just to secure the screw in there quickly, and he probably couldn’t imagine why anyone would ever need to remove the screws. And because it’s not _his_ fan, he’s thinking this is probably the last time he’ll be seeing me.

Well, surprise him! If you get the ruined screws out, send them to his boss… with a little note.

The sad truth is, as long as it works, nobody would care. Not even his boss. That’s the way things are around here. In fact, the average Joe would probably never see the screws.

It’s not using a drill as a screwdriver that’s the problem here, I use one myself all the time without results like this, it’s the user that’s at fault. If you use a drill as a screwdriver then it needs high torque at low speed and idaelly a clutch, though I have never had a problem without a clutch. There are several things which could have caused the damaged shown:

1. The drill didn’t stop when the screw was fully home and continued to try to drive the screw in at full torque and downward pressure.

2. The wrong bit was used – it’s a very common mistake, there are three main types (and different sizes) – Philips, Cross Head and Posidrive, they are all different. Even using a wrong screwdriver would cause head damaged if the wrong one is used.

3. The screw was to long for the wood type, if it’s hard wood then only a short screw is needed – unless you are pre-drilling the holes which is the best way.

This guy obviously carried out poor workmanship and probably didn’t give a damn, Somebody could have injured themselves on this and then you could have sued 🙂

Hi John, thanks for the insightful comment! When I wrote this post it was meant as a rant. I actually have a drill with a clutch (I didn’t know it was called a “clutch”), so I know that proper use of the drill will not result in this.

From what I saw, his drill did not have a clutch, and it was probably not pressed in correctly and/or the wrong driver bit was used, thus causing it to slip and damage the screw. In fact I think he did it intentionally to make sure the screw was tight. Very shoddy workmanship.

i use my drill for screwdriver all the time to but i set the clutch on it properly with the right bits and ive never stripped the heads.

I have a set of screw unscrewers for my drill for overcoming the bad workmanship that you find like this – they were £4 from Aldi – one of the best tools I ever bought.

Use a large rubber band across the ruined screw head and this should allow you to use Phillips to remove it. Just an idea.

I think removing it is definitely possible, there are many methods, yours being one of them. Problem is the process will most probably destroy the screw (but hopefully not the fixture). What this guy did was make this a one-way trip, which is not how screws are supposed to work.

Thankk you for writing this